+86-0577 56666518 info@tinsi-steel.cn

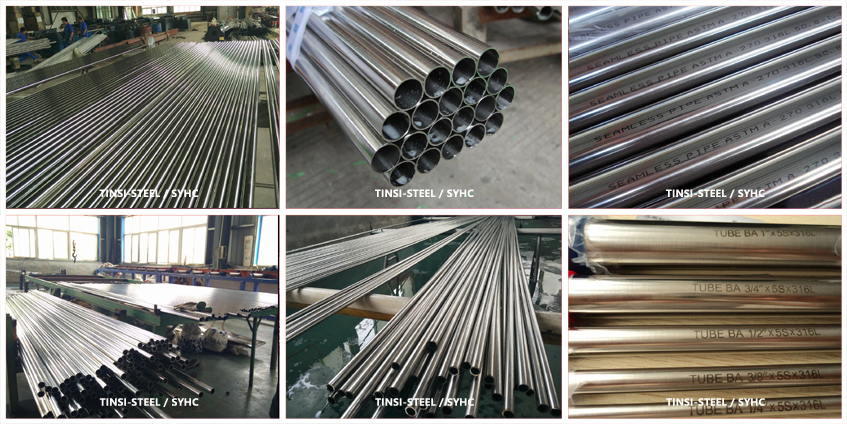

TINSI is a Professional manufacturer of stainless steel precision Bright Annealed Tubes, which is being made up from High Quality of Standard Raw Materials. Owing to the expertise and proficient team of diligent personnel, we are offering a wide and comprehensive range of these tubes. We have a pride in presenting a comprehensive collection of innovative, high-class and customizable Precision Bright Annealed Stainless Steel Tubes by using state-of-art technology. We offer this tubes&pipes in different grades, thickness, size and specification according to requirements of our customers, Aiming to satisfy our clients, we are engaged in offering a high quality Stainless Steel precision Bright Annealing polish sanitary Seamless Pipes.

|

stainless steel sanitary or precision tubes&pipes |

|

|

Description |

stainless steel sanitary or precision tubes&pipes: outer diameter 8-114mm, wall thickness 0.5-4mm.Main standards:ASTM A270/ASTM A632/ASTM A511/etc.Precision pipes are processed again by precision cold rolling or drawing with seamless or welded industrial tubes as mother tube.it more precise tolerance and high quality by precise process make inner and outer finish surface smooth that maximum tolerance size accuracy ±≤0.02-0.05mm. inner wall roughness Ra < 0.7 um and after polishing Ra < 0.4-0.25 um.Mainly used hardware equipment of automation, medical, beer, precision instrumentation,etc.Usually BA ( bright annealing after rolling surface) or MB (finish rolling bright surface) or MP (MB+polishing) |

|

Process Method |

Seamless cold precision drawn&cold precision rolling |

|

Standard |

ASTM A270,ASTM A 269,ASTM A632,ASTM A511,EN10216-5,ISO1127,etc |

|

Material Grade |

Mainly:TP304,TP316L |

|

Outer Diameter |

8mm-114mm |

|

Thickness |

0.8mm-4mm |

|

Length |

5-7Mtr of ready stock or as customers' request. Max about 10Mtr |

|

Tolerance |

OD/ID :±0.05--±0.15mm ; THK :±0.05--±0.15mm; within standard |

|

Surface |

MB (finish rolling bright)or BA ( bright annealing) or MP (MB+polish) |

|

Test |

Dimension Examination,PMI,Roughness,UT, ET, HT, RT,etc, |

|

Application |

Automation equipment, Hydraulic system,Medical,Precision instrument and parts, Electric heat pipe, Automobile,etc |

Typical application key word :

|

precision tubes pipes tubing |

Polish tubes pipes tubing |

|

Precision rolling tubes pipes tubing |

Sanitary tubes pipes tubing |

|

precision drawn tubes pipes tubing |

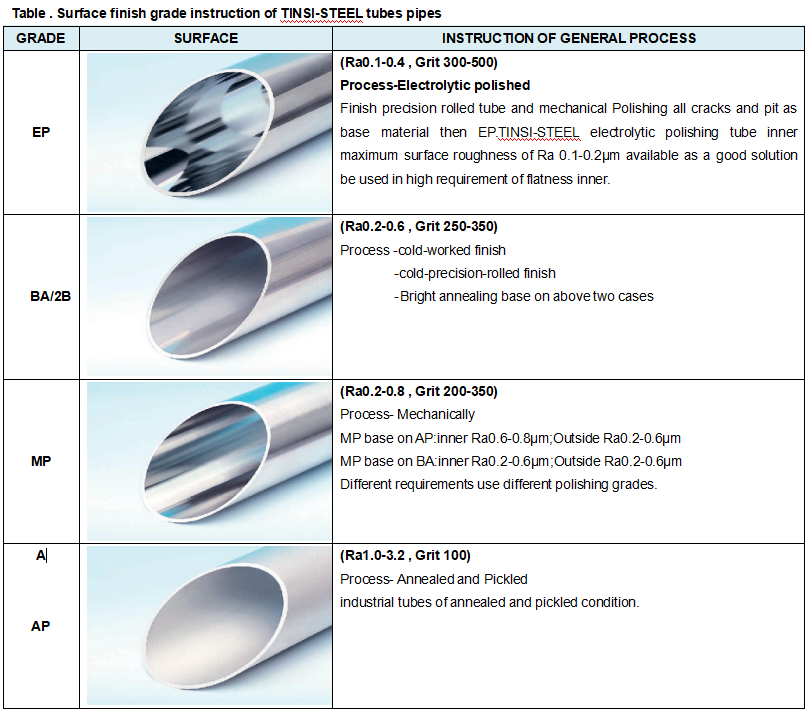

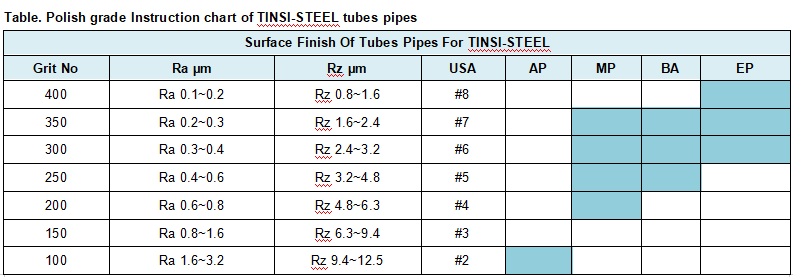

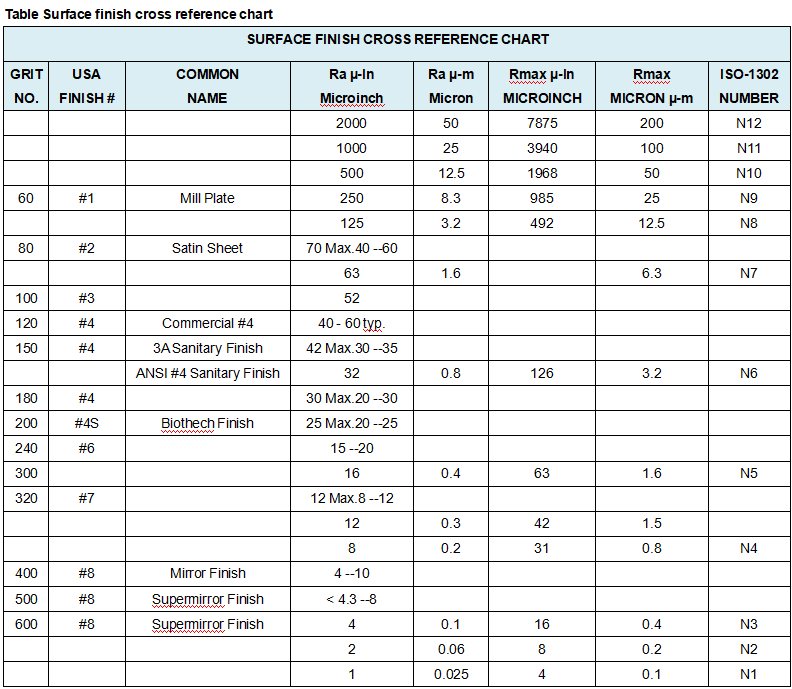

Surface grade |

|

Bright annealed tubes pipes tubing |

|

|

BA tubes BA pipes BA tubing |

|

|

instrumentation tubes pipes tubing |

|

|

Hydraulic tubes Pipes tubing |

|

|

Mechanical tubes pipes tubing |

|

Advantage of bright annealing precision tubes&pipes of TINSI-STEEL

1.More precise dimension

TINSI steel using the high quality industrial raw materials pipe produced by ourselves and advanced three-roller-precision-cold-rolling technology, making the close dimension controls. tinsi-steel using precision rolling or precision draw processing repeatedly more times for high precision requirements tubes.so that tinsi tube more characterized by precise diameter tolerance ovality, eccentricity and controlled hardness for superior performance of precision systems.

2. Better mechanical property

TINSI using bright annealing method, the temperature of furnace can reach more than 1350℃, and the tolerance for the setting and real temperature can be controlled within +/-10℃, which is impossible for the traditional annealing.

3. Superior surface finish

The traditional annealing method is performed in a so called open furnace, where the atmospheric oxygen causes scaling of the heat treated materials, which makes the surface rough. We tinsi steel usually uses bright annealing process to produce stainless steel precision tubes,the heat treatment is performed in a so called closed furnace. The heat treated materials is protected by an inter gas atmosphere, which guarantees the oxygen cannot enter the furnace or come in to contact with the materials and react to form scale on or tarnish the materials. The surface finish is clean, bright and precision, which is an excellent starting point for further process, like electro-polishing and mechanical polishing.

4. Perfect inspection method and inspection equipment

TINSI more dimension test and strict quality control in production,and ensure the quality to meet various requirements of each tube, we also more strict test such as PMI test, Hydraulic, inner cleaned by sponge, dimension test, and surface test.

What’s more, TINSI offer precision drawn tubing that the quality is similar to precision rolling, but has more advantage on price.

Bright annealing Irreplaceable application in stainless steel tubes&pipes of TINSI-STEEL

The surface finish is clean, bright and precision, which is an excellent starting point for further process, like electro-polishing and mechanical polishing.

Especially for the tube with length more than 12 meters, the traditional pickling tube is very hard to clean the inner surface, however, with the bright annealing method, the tubing is much cleaner, smoother on both inner and outer surfaces.And tinsi-steel also used for small diameter capillary and needle tube to ensure the inner hole is clean

Contact: Hyman.C

Phone: 15825401620

Tel: +86-0577 56666518

Email: info@tinsi-steel.cn

Add: factory address: no272,Yongning West Road,Xiping Street, Songyang,Li shui,China