+86-0577 56666518 info@tinsi-steel.cn

Contents

l Stainless steel tubes & pipes applications Introduction of Tinsi-steel

l Industrial tubes & pipes of Tinsi-steel

l Sanitary and precision tubes&pipes of Tinsi-steel

l Capillary (small tubes&pipes) of Tinsi-steel

l Needle tube(micro capillary)of Tinsi-steel

l Needles piping of Tinsi-steel

Wenzhou tinsi-steel Co.,Ltd is one of the leaders manufacturer & stockist & exporters in stainless steel Pipes &Tubes.tinsi-steel team professional more than 20 years focus on manufacturing stainless steel tubes&pipes and Duplex steel tubes&pipes and Nickel alloy tubes&pipes around full-size include small and big(Size range OD:0.4-426MM WT:0.1-40MM).we classify tubes&pipes according to production process and application into 5 kinds: industrial pipes&tubes / precision pipes&tubes / sanitary pipes&tubes / capillary / needle pipes&tubes / detailed description as below

Typical applications field kind of TINSI-STEEL stainless steel tubes pipes

|

Boiler Tubes Pipes |

In power generation plants in applications such as reheaters and superheaters |

|

Heat Exchanger Tubes Pipes |

Serving e.g. refineries(petroleum),chemical and pharmaceutical industries as well as fertilizer production and food industries |

|

Furnace Tubes Pipes |

Industrial furnaces and similar applications demand our heat-, high temperature- and corrosion resistant austenitic steel (usually with high carbon contents) and nickel-based alloys |

|

Nuclear Tubes Pipes |

(Power Gen, Waste treatment, Fuel fabrication) NSSS piping, Heat exchanger tubes (U-bent & straight), In-core instrumentation tubes, Instrumentation tubes for quality class 1, 2, 3 of the nuclear power application |

|

Oil and Gas Tubes Pipes |

OCTG (Oil Country Tubular Goods),Onshore and offshore oil and gas exploration and production need special tubular products to cope with high pressure and/or high temperature conditions as well as with highly aggressive substances |

|

Umbilical Tubes Pipes |

Subsea applications have to withstand aggressive sea water and must be essentially inert to the commonly used fluids transmitted through the tubes |

|

Instrumentation Tubes Pipes |

Used in several market segments (e.g. chemical, Oil & Gas, ...) for analyse systems, measurement instruments and hydraulic circuits |

|

Hydraulic tubes pipes |

Hydraulic and instrumentation Precision mechanical engineering Automotive Industries. |

|

Hollow Bar and Mechanical Tubes Pipes |

Our tubes as highly efficient quality raw material for radially machined components and a favorable alternative to use of solid bars |

|

Other Upstream and Downstream Applications |

These comprise e.g. Subsea Flowline, Risers and Piping systems, Surface Piping and Line pipes |

|

•General Tubes & Pipes |

Apart from the above mentioned special applications, we also offer tubes for general use and different corrosion and heat resistant applications |

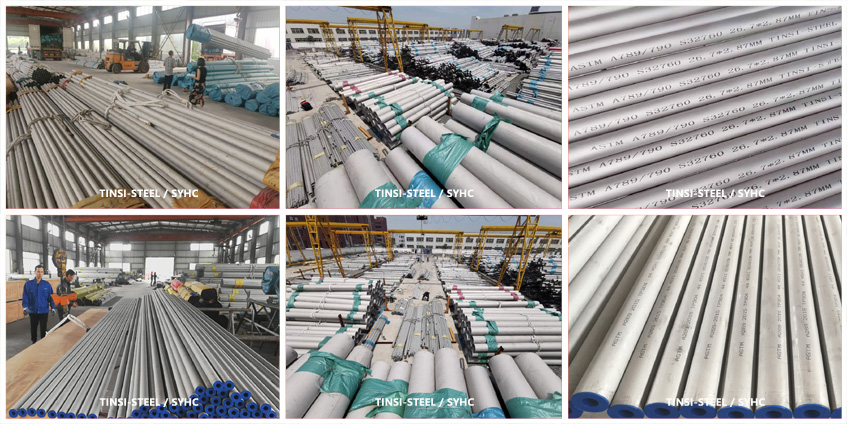

1.Stainless steel industrial tubes&pipes:(TINSI-STEEL ready stock more than 2000 tons available in seamless tube )

|

Stainless steel industrial tubes&pipes introduction form |

|

|

Description |

stainless steel seamless tubes&pipes. outer diameter 6-426mm, wall thickness 0.9-25mm. The main standards:ASTM A312/ASTM A213/ASTM A269/etc.Seamless stainless steel tube&pipe main production process is cold drawing/cold rolling. delivery generally as annealing and pickling. We are keep about 1500 tons ready stock.Now we classify pipes into three different quality and packaging levels to provide the most suitable price and suitable quality for people in different parts of the world.Mainly used in chemical industry, boilers and other industries.Usually delivery in AP (annealing and pickling) and some is MP (AP + mechanical polishing). |

|

Process Method |

Seamless cold drawn&cold rolled / Welded Pipe |

|

Standard |

ASTM A312, ASTM A213, ASTM A249, ASTM A270, ASTM A269, ASTMA790, ASTM B622, ASTM B516,ASTM A789, EN10216-5, etc |

|

Material Grade |

Austenitic:TP304,TP304L,TP316,TP316L,TP347,TP347H,TP321,TP321H,TP310,TP321 |

|

Duplex steel:SAF2205/S31803/1.4462/F51, S32205/F60, S32760/1.4501/F55, |

|

|

Nickel alloy:Incoloy800/800H/800HT ,Incoloy825 ,Incoloy925(N08925) , Inconel600/Inconel601/Inconel602ca, Inconel625 , HastelloyC-276/C-2000/C-22 , HastelloyB/B2/B3 ,G30 ,G35 |

|

|

Monel:400 ,K500 |

|

|

Outer Diameter |

Seamless Pipe: 6mm-530mm 1/8"-28" (DN5-DN500) |

|

Thickness |

Seamless Pipe: 0.8mm-35mm SCH5/SCH10/SCH40/SCH80/SCH160/XXS |

|

Length |

5-7Mtr of ready stock or as On-demand customization. Max about 12Mtr |

|

Tolerance |

OD/ID :±0.1-2mm ; THK :±5-10% ; within standard |

|

Surface |

AP(Annealed and pickling) / MP(mechanically polish) |

|

Test |

Dimension,Visual Examination,PMI,UT, ET, HT, RT,etc, |

|

Application |

Petroleum, Chemical, Medical Devices, Aerospace, Nuclear Power, Shipbuilding, High Pressure Boiler, Hot Delivery, Pressure Vessel, Condenser, Water Conservancy, Electric Industry |

Typical application key word:

|

Stainless steel boiler tubes pipes |

Polish tubes pipes tubing |

|

stainless steel U bend tubes pipes |

Sanitary tubes pipes tubing |

|

Stainless Steel Heat Exchange tubes pipes |

|

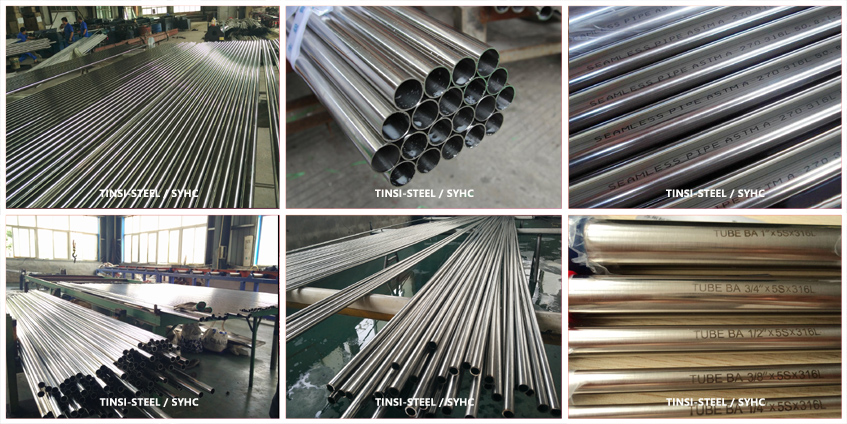

2.stainless steel sanitary or precision tubes&pipes

|

stainless steel sanitary or precision tubes&pipes |

|

|

Description |

stainless steel sanitary or precision tubes&pipes: outer diameter 8-114mm, wall thickness 0.5-4mm.Main standards:ASTM A270/ASTM A632/ASTM A511/etc.Precision pipes are processed again by precision cold rolling or drawing with seamless or welded industrial tubes as mother tube.it more precise tolerance and high quality by precise process make inner and outer finish surface smooth that maximum tolerance size accuracy ±≤0.02-0.05mm. inner wall roughness Ra < 0.7 um and after polishing Ra < 0.4-0.25 um.Mainly used hardware equipment of automation, medical, beer, precision instrumentation,etc.Usually BA ( bright annealing after rolling surface) or MB (finish rolling bright surface) or MP (MB+polishing) |

|

Process Method |

Seamless cold precision drawn&cold precision rolling |

|

Standard |

ASTM A270,ASTM A 269,ASTM A632,ASTM A511,EN10216-5,ISO1127,etc |

|

Material Grade |

Mainly:TP304,TP316L |

|

Outer Diameter |

8mm-114mm |

|

Thickness |

0.8mm-4mm |

|

Length |

5-7Mtr of ready stock or as customers' request. Max about 10Mtr |

|

Tolerance |

OD/ID :±0.05--±0.15mm ; THK :±0.05--±0.15mm; within standard |

|

Surface |

MB (finish rolling bright)or BA ( bright annealing) or MP (MB+polish) |

|

Test |

Dimension Examination,PMI,Roughness,UT, ET, HT, RT,etc, |

|

Application |

Automation equipment, Hydraulic system,Medical,Precision instrument and parts, Electric heat pipe, Automobile,etc |

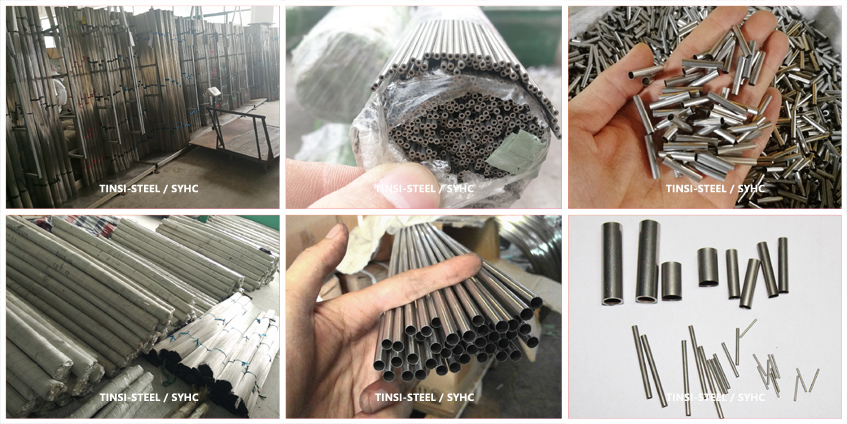

3.Stainless Steel Capillary OD:3-12mm THK:0.3-2mm

|

Stainless Steel Capillary OD:3-12mm THK:0.3-2mm |

||

|

Description |

stainless steel capillary: outer diameter 3-15mm,wall thickness 0.3-1mm. Main standards:GB 3090/ASTM A632.Also seamless or welded pipes could be available.production process is high frequency automatic welding and cold drawing/cold rolling, specifications could be booking depend customized and less ready stock. Mainly used in automation equipment,hydraulic system,medical,precision instrument and parts,electric heat pipe,automobile,etc. Usually (soft state) BA (bright annealing)and part of MP (MB+polishing) |

|

|

Process Method |

Seamless cold drawn&cold rolled |

Welded Pipe with cold drawn |

|

Standard |

ASTM A270,ASTM A 269,ASTM A632,ASTM A511,EN10216-5,ISO1127,etc |

|

|

Material Grade |

Austenitic:TP304,TP304L,TP316L,TP347H,TP321,TP310S,etc |

Mainly:TP304/TP316L |

|

Duplex steel:S31803,S32750,S32760,904L |

||

|

Nickel alloy:Incoloy800,825,925, |

||

|

Outer Diameter |

3mm-12mm |

3-12mm |

|

Thickness |

0.5mm-2mm |

0.2-1mm |

|

Length |

3-4Mtr of normal,Max about10Mtr |

2-5 fixed length |

|

Tolerance |

OD/ID :±0.04-0.15mm ; Thk :±0.04-0.15mm ; within standard |

OD/ID :±0.02mm ; THK :±0.02mm ;within standard |

|

Surface |

Normally BA (bright annealing)and part of MP (MB+polishing) |

|

|

Test |

UT, ET, HT, RT,etc, and others as the requests of the customers |

|

|

Application |

Automation equipment, Hydraulic system,Medical,Precision instrument and parts, Electric heat pipe, Automobile,etc |

|

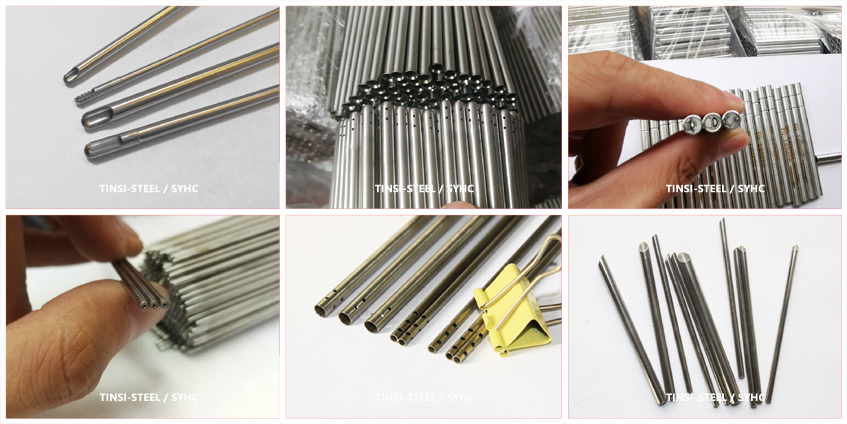

4.stainless steel needle tube(micro capillary)

|

stainless steel needle tube(micro capillary) |

|

|

Description |

stainless steel needle tube(micro capillary tube): outer diameter 0.4-3mm, wall thickness 0.1-0.3mm. This kind pipe mainly welded pipe. standard GB 18457,ASTM A908,EN.ISO 9626, Production process is high frequency automatic welding and precision coil cold drawing.tolerance size accuracy ±≤0.02mm.delivery generally surface in bright smooth.Mainly used in Medical industry,antenna, textile, electric heat, temperature sensor,LED,etc |

|

Process Method |

Welded +Cold drawn |

|

Standard |

GB18457,ASTM A908,ISO 9626, |

|

Material Grade |

Mainly:TP304, TP304L, TP316L |

|

Outer Diameter |

0.4mm-3mm |

|

Thickness |

0.08mm-0.3mm |

|

Length |

2-2.5 Mtr fixed length |

|

Tolerance |

OD/ID :±0.02mm; THK :±0.01-0.02mm; within standard |

|

Surface |

MB(machining Bright smooth) |

|

Test |

Dimension,Visual Examination,PMI,etc |

|

Application |

Medical industry,medical needles,antenna, textile, electric heat instrument, temperature sensor,LED,precision instrument,etc |

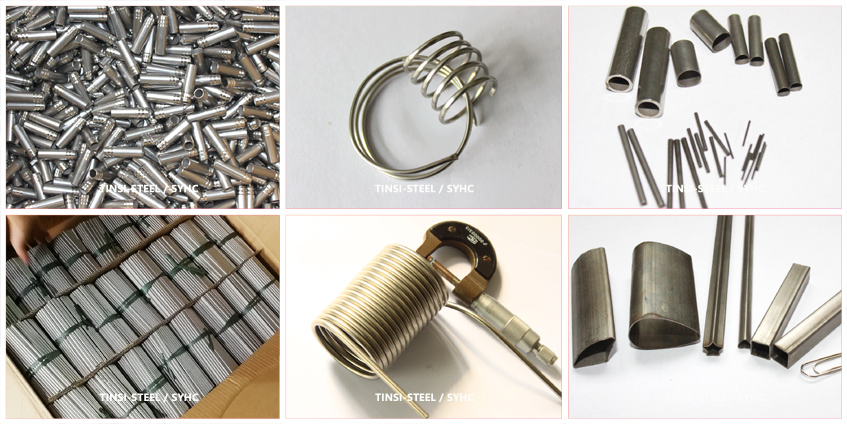

5.stainless steel needles&piping

|

stainless steel needles&piping |

|

|

Description |

5.stainless steel needles&piping, outer diameter 0.4-6mm, wall thickness 0.1-1mm. medical injection needles, blood collecting needles, veterinary needles, all kinds of puncture needles,hole needles, breathing needles, dispensing needles, ink needles, beauty needles, milk needles, sweater needles and other industrial and medical applications. In addition, stainless steel capillary material can be cut, deburre, polish, sharpen, tipping, drilling, stamping etc process. |

|

Process Method |

cut, deburre, polish, sharpen, tipping, drilling, stamping etc process. |

|

Application |

medical injection needles, blood collecting needles, veterinary needles, all kinds of puncture needles,hole needles, breathing needles, dispensing needles, ink needles, beauty needles, milk needles, sweater needles and other industrial and medical applications. |

Contact: Hyman.C

Phone: 15825401620

Tel: +86-0577 56666518

Email: info@tinsi-steel.cn

Add: factory address: no272,Yongning West Road,Xiping Street, Songyang,Li shui,China