+86-0577 56666518 info@tinsi-steel.cn

Type,grade and method about polish tubes & pipes of TINSI-STEEL

TINSI-STEEL generally there are three type method of polished tubes & pipes:

1.polish base on open annealing and pickling industry tube of seamless tube,

2.polish base on cold-rolled-tube or cold-precision-rolled bright annealing tubes&pipes. some time without bright annealing(seamless sanitary tube).

3. polish base on 2B surface of welded tube(welded sanitary tube).

Also TINSI-STEEL there are totally four type method process of polished tubes&tubes:

1.Polishing

2.Brushing.

3.Buffing.(1-3:Mechanical Polishing-MP)

4.Electrolytic(EP).

And TINSI-STEEL customized available accroding difference requirement to be excellent quality with rich experience and exquisite workmanship.

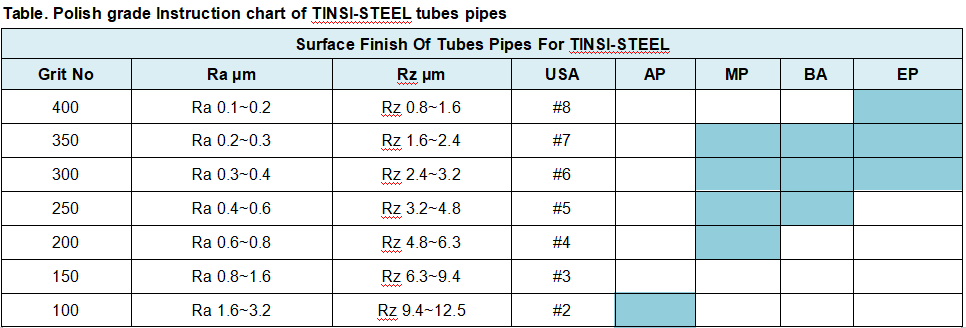

Table . Surface finish grade instruction of TINSI-STEEL tubes pipes

|

GRADE |

SURFACE |

INSTRUCTION OF GENERAL PROCESS |

|

EP

|

|

(Ra0.1-0.4 , Grit 300-500) Process-Electrolytic polished Finish precision rolled tube and mechanical Polishing all cracks and pit as base material then EP.TINSI-STEEL electrolytic polishing tube inner maximum surface roughness of Ra 0.1-0.2µm available as a good solution be used in high requirement of flatness inner. |

|

BA/2B

|

|

(Ra0.2-0.6 , Grit 250-350) Process -cold-worked finish -cold-precision-rolled finish - Bright annealing base on above two cases

|

|

MP

|

|

(Ra0.2-0.8 , Grit 200-350) Process- Mechanically MP base on AP:inner Ra0.6-0.8µm;Outside Ra0.2-0.6µm MP base on BA:inner Ra0.2-0.6µm;Outside Ra0.2-0.6µm Different requirements use different polishing grades.

|

|

AP

|

|

(Ra1.0-3.2 , Grit 100) Process- Annealed and Pickled industrial tubes of annealed and pickled condition. |

Table Surface finish cross reference chart

|

SURFACE FINISH CROSS REFERENCE CHART |

|||||||

|

GRIT |

USA |

COMMON |

Ra µ-In |

Ra µ-m |

Rmax µ-In |

Rmax |

ISO-1302 |

|

|

|

|

2000 |

50 |

7875 |

200 |

N12 |

|

|

|

|

1000 |

25 |

3940 |

100 |

N11 |

|

|

|

|

500 |

12.5 |

1968 |

50 |

N10 |

|

60 |

#1 |

Mill Plate |

250 |

8.3 |

985 |

25 |

N9 |

|

|

|

|

125 |

3.2 |

492 |

12.5 |

N8 |

|

80 |

#2 |

Satin Sheet |

70 Max.40 --60 |

|

|

|

|

|

|

|

|

63 |

1.6 |

|

6.3 |

N7 |

|

100 |

#3 |

|

52 |

|

|

|

|

|

120 |

#4 |

Commercial #4 |

40 - 60 typ. |

|

|

|

|

|

150 |

#4 |

3A Sanitary Finish |

42 Max.30 --35 |

|

|

|

|

|

|

|

ANSI #4 Sanitary Finish |

32 |

0.8 |

126 |

3.2 |

N6 |

|

180 |

#4 |

|

30 Max.20 --30 |

|

|

|

|

|

200 |

#4S |

Biothech Finish |

25 Max.20 --25 |

|

|

|

|

|

240 |

#6 |

|

15 --20 |

|

|

|

|

|

300 |

|

|

16 |

0.4 |

63 |

1.6 |

N5 |

|

320 |

#7 |

|

12 Max.8 --12 |

|

|

|

|

|

|

|

|

12 |

0.3 |

42 |

1.5 |

|

|

|

|

|

8 |

0.2 |

31 |

0.8 |

N4 |

|

400 |

#8 |

Mirror Finish |

4 --10 |

|

|

|

|

|

500 |

#8 |

Supermirror Finish |

< 4.3 --8 |

|

|

|

|

|

600 |

#8 |

Supermirror Finish |

4 |

0.1 |

16 |

0.4 |

N3 |

|

|

|

|

2 |

0.06 |

8 |

0.2 |

N2 |

|

|

|

|

1 |

0.025 |

4 |

0.1 |

N1 |

Contact: Hyman.C

Phone: 15825401620

Tel: +86-0577 56666518

Email: info@tinsi-steel.cn

Add: factory address: no272,Yongning West Road,Xiping Street, Songyang,Li shui,China